KUANGING FABRICS

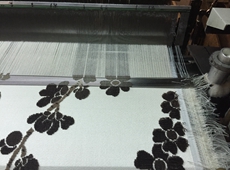

Kuanging utilizes a 10,000 square meter facility in Taiwan and a 25,000 square meter facility in China. Our factories include: weaving looms, jacquard heads, spinning, warping, inspecting and packing stations, as well as designated computer-aided design (CAD) software and testing laboratories. We are fully stocked in order to prepare exactly what our clients specify.

Our technical department is available to answer any questions regarding product performance, applications, durability, maintenance, and the physical properties of our products.

The development wing, on the other hand, specializes in creative solutions to client requests using our practical knowledge to create innovative content. Lastly, our manufacturing division is well trained, dedicated, and has the experience and enthusiasm that is needed to create high quality products. At Kuanging, our teams are standing by to fulfill all of your requests and we would be pleased to answer any questions that you might have.